The Precision and Versatility of Diecasting

The Precision and Versatility of Diecasting

Blog Article

Diecasting is an essential manufacturing technique that requires forcing molten metal into a mold cavity under high pressure. It is well-known for its capability to create complex designs that are characterized by a high degree of accuracy and repeatability, making it indispensable in various sectors. From aerospace and automotive all the way to household appliances and consumer electronics diecasting plays a significant component in making products that can meet the strictest standards for quality and performance. This article focuses on the intricacies of diecasting, highlighting its advantages, processes and uses.

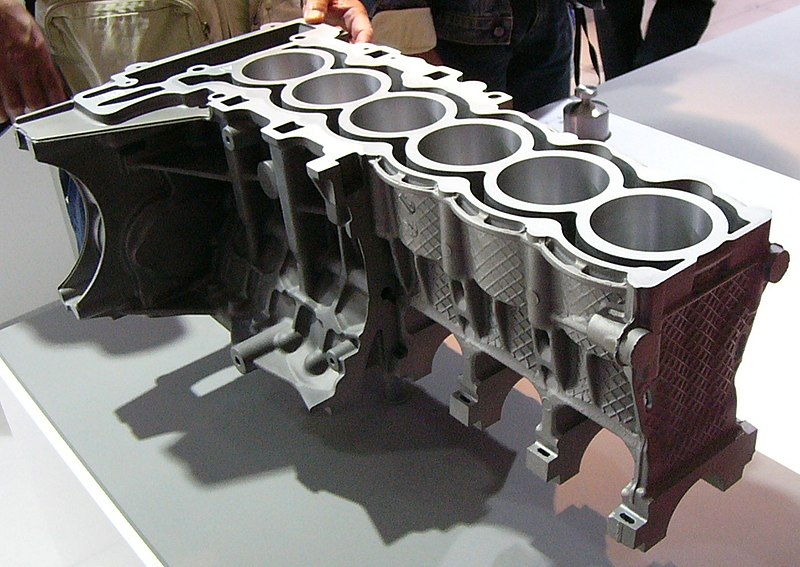

Diecasting begins with the design of a mold, known as a "die," which is made of hardened steel to withstand high pressures and temperatures. After the mold has been made the metal alloys like aluminum, zinc, magnesium or copper, are heated until they turn molten. This molten metal is then introduced into the mold at great pressure. It completely fills the mold. This includes intricate sections and thin walls. The pressure is maintained until the material has solidified, after which the die is reopened, and the part that has been formed is then ejected. The high pressure method guarantees that the final product is precise without the need for extra machining or final.

One of the main benefits of diecasting is its effectiveness when it comes to mass production. Once the dies are fabricated this process is able to be repeated hundreds or thousands times, with no variation in components. This high repeatability is crucial when it comes to industries that require massive volumes of identical components. Additionally, diecasting is known for its efficiency in manufacturing. It produces less waste compared to other techniques for forming metal, as excess metal can be recycled and used again. This reduces not just the cost of material but can also help to create greener manufacturing methods. The combination of accuracy, speed as well as material efficiency make diecasting an appealing choice for production in high volumes.

Diecasting also offers considerable benefits in terms of mechanical properties and performance. Diecast parts are known for their strength and durability that are crucial features for parts used for demanding tasks. The fine-grain structure that forms in the process of rapid cooling metal is a key factor in the desirable characteristics, which makes diecast products suitable to be used in high-stress environments. Furthermore, the process of diecasting permits the inclusion of thin walls and complicated characteristics without jeopardizing the integrity of the finished product. This is especially beneficial in the automotive and aerospace industries where the ability to reduce weight but maintaining strength in the structure is vital to increase fuel efficiency and overall efficiency. To get supplementary details kindly head to https://www.senadiecasting.com.my/

Diecasting materials are crucial in determining the characteristics and the performance of the final product. Aluminum is among the most popular materials used due to its outstanding strength-toweight ratio, corrosion resistance, and good thermal and electrical conductivity. Zinc alloys are also popular providing high durability, strength, as well as the capability to create components with fine particulars. Magnesium alloys offer the benefit that they are the tiniest structural metal, making them perfect for use in areas where weight reduction is crucial. Copper alloys are somewhat less popular, are used because of their excellent electrical conductivity and resistance to corrosion. The decision to select a material rests upon the specifications of the application, including physical properties, physical conditions in the environment, and also cost considerations.

Diecasting is the pinnacle in manufacturing technology. It offers accuracy, efficiency, and versatility which is unparalleled by other methods. The ability to create intricate, high-end components that have superior mechanical properties makes it essential in various industries, from automotive to consumer electronics. The efficiency and material savings associated with diecasting highlight its importance in large-scale production. Furthermore, its ability to adapt makes it able to satisfy the changing demands of modern manufacturing. In the midst of industries pushing the boundaries of innovation and productivity, diecasting is expected to continue to be an essential tool making advancements possible and supporting the development of new products that shape our world.